Get Started 3D Printing

Getting started with 3D printing can be baffling, to say the very least. With so many new things to learn, newcomers can find it extremely hard to figure out where they should begin .There are many questions that need to be answered before you actually take the plunge and enter the world of 3D printing.

This chapter will focus on answering the common questions that perplex a novice – such as yourself – when they attempt to understand the complexities of the 3D printing technology.

Do You Really Need a 3D Printer?

Desktop 3D printers can now be purchased at affordable rates. The question that needs to be answered is whether you really need to get a 3D printer of your own. There are a great number of online resources that can print models and deliver them to you.

So if you only need to get something printed occasionally, then it would be best to simply send a blueprint of the object to one of these services, and avoid all the hassle completely.

If You Do, Which Printer Should You Buy?

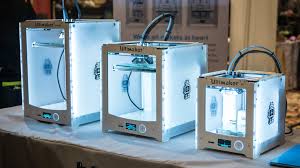

Let’s be honest here … you will probably want to buy a 3D printer of your own – it’s one of the most exciting purchases you will ever make! You will need to choose between buying a pre-assembled machine, and getting one that you have to build yourself. Both routes come with their own set of advantages and disadvantages. If you’re blessed with do-it-yourself skills and a fair bit of technical knowledge, you may find the latter option more appealing. Building your own 3D printer will also cost you less, but it sure isn’t for the faint hearted.

One thing to bear in mind with constructing your own kit set 3D printer is that anything goes wrong with the 3D printer down the track, you’ll already have the necessary experience to disassemble it and put it back together again.

The great thing with 3D printing is that the prices of printers are coming down, while at the same time the choice and quality of these same printers is going up.

Where Can You Get 3D Model Files?

When it comes to the actual design blueprints of the objects, you have two options: you can either get them online ready-to-go, or make your own.

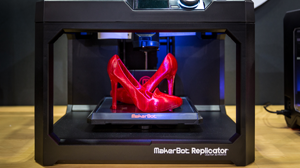

You can find all kinds of models on a website called the Thingiverse. Even though this website is owned by the renowned manufacturers of the Replicator printer, Makerbot, it still contains a decent inventory of blueprints by ordinary users.

If you insist on making your own models (this is the best part!), then proceed to the next question below.

How Can You Make Your Own Models?

There was a time when Computer Aided Design (CAD) software was designed by engineers, for engineers. This software used to be extremely complex (to an extent it still is complex … but is more manageable now) and no one except those with the proper training could use CAD software effectively.

CAD software has a steep learning curveTimes have changed, and the latest in CAD software is aimed at general users. The best thing about modern CAD software is that it is not as difficult to learn and use as it was previously; however, the learning curve is still pretty steep, and you would need to dedicate quite a bit of your time and effort to fully grasp all the concepts of 3D printer-ready design using CAD.

In order to learn the basics of CAD designing software, check out Autodesk’s 123D Design and Inventor Fusion. Both of these programs are free for limited licences. You can use the free versions of these software tools to design models for printing.

One thing to bear in mind, however, is that the free/limited/student versions of CAD software do not generally allow you to sell your printed objects, or to sell the files you create. As always, you need to do your own due diligence and investigate the licensing for any software you download.

If you plan on 3d printing as a business, then you really do need to invest in a commercial software licence.

Can You Simply Scan Real Objects And Print Them?

A lot of people wonder whether it is possible to ‘simply scan and print’ objects. It is possible, and there are a few companies that create dedicated 3D scanning equipment, such as Go!SCAN 3D. However,the scanned models generally require a lot of tweaking before they can be used to print objects.

This idea is undoubtedly ingenious, but it will take a little time to mature; at present you are still better to create the files “by hand” and then print them from there.

How Should You Go About Printing Downloaded Models?

If you have downloaded model blueprints from websites like Thingiverse, chances are that they will already be in STL format. This format is halfway to becoming a printable file … so stay tuned for how to turn that STL file into something seriously awesome.

For the printer to be able to manage the design files, they have to be sliced – which means that it has to be transformed into the exact layer-by-layer description of the object, including the temperature, the speed and wall thickness controls. The resulting file is called a G-Code file that can be interpreted by the printer.

You can choose from a number of slicing applications in the market, including free ones such as ReplicatorG, Cura and KISSlicer. We will talk more about slicing software shortly.

How Should You Go About Printing Models That You Created?

Slicing software is an important tool required to create a final, printable fileIf you used computer-aided design software to create your model, then the software will be able to export it as an STL file. All you would have to do would be to use a slicing software program to transform it into a G Code file.

On the other hand, if you used a 3D program such as Photoshop, Sketchup or any other 3D design program that isn’t specifically designed for CAD, then the process of getting the G code file requires several steps.

Once of the first things that need to be done is to see whether the 3D model is genuinely printable or not. In most cases, minor changes will be required, such as patching up of holes and repairing of vertices.

Secondly, the file will need to be converted into an STL before it can be sliced for the printer.

You can use a free, open-source application called Meshlab to perform both the tasks of patching up the model and generating the STL file. You may also want to look into a commercial program called NetFabb that can generate the G Code files as well.

Where Can You Buy the Material?

The printing material (or filament) that is required for the 3D printer comes in two types: PLA and ABS.

PLA is Polylactic Acid, a form of polyester that is made from a variety of natural sources including sugar, corn starch or sugar cane. It is biodegradable and melts at temperatures lower than ABS.

ABS, or Acrylonitrile butadiene styrene is a type of polymer that is oil-based. It is extremely strong and resilient and is commonly used to create children’s toys.

You can purchase them in loose forms or as a reel from a wide range of sources. A kilogram of 3.0mm ABS filament reel costs around $30 on Amazon, which is where we recommend you buy your filament from. Search around to find the best deal and the lowest shipping cost for your location.

Testimonials